细粉加工设备(20-400目)

我公司自主研发的MTW欧版磨、LM立式磨等细粉加工设备,拥有多项国家专利,能够将石灰石、方解石、碳酸钙、重晶石、石膏、膨润土等物料研磨至20-400目,是您在电厂脱硫、煤粉制备、重钙加工等工业制粉领域的得力助手。

超细粉加工设备(400-3250目)

LUM超细立磨、MW环辊微粉磨吸收现代工业磨粉技术,专注于400-3250目范围内超细粉磨加工,细度可调可控,突破超细粉加工产能瓶颈,是超细粉加工领域粉磨装备的良好选择。

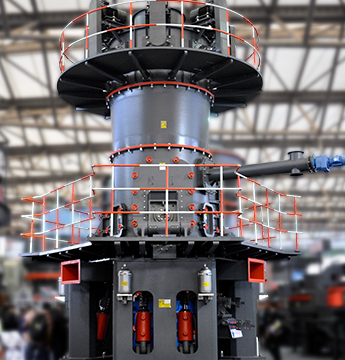

粗粉加工设备(0-3MM)

兼具磨粉机和破碎机性能优势,产量高、破碎比大、成品率高,在粗粉加工方面成绩斐然。

Mining Ore Classifier For Froth Flotation

Frothers in flotation: A review of performance and function

2024年2月1日 Two of the most important classes of surfactants adsorbing primarily at solid–liquid interface are: (i) collectors, which increase the hydrophobicity of the mineral particles to be floated (AbakaWood et al, 2017, Liu et al, 2017, Tian et al, 2017, Wang et al, 2016, On the practical side, arguments can be made that bubble size is a key driver through its contribution to bubble surface area flux (S b), and hencView Article2024年3月1日 Using imageprocessing algorithms, the extracted features from the flotation froth include: the texture, the bubble size, the velocity and the color distributionHybrid features extraction for the online mineral grades 2024年11月27日 Flotation machines can be classified by energy input mechanism (pneumatic or mechanical), the location at which the energy input occurs (single chamber or dual chamber), Froth Flotation’s Newest Machines: How Much Better Are 1 天前 Achieve optimal mineral ore recovery with minimal impact on the environment The Pineer froth flotation process enables sustainable and costeffective spodumene/lithium ore recovery Comes from one supplier, Lithium Ore Flotation Plant Pineer Mining 2024年10月9日 Froth flotation is super versatile It helps us extract valuable metals like lead, copper, and zinc from their ores, making it a vital part of modern mining It’s also used for cleaning up coal and processing a wide variety of Froth Flotation: Separating Minerals Like a Pro

.jpg)

1 Froth Flotation – Fundamental Principles

2009年8月27日 Froth flotation is a highly versatile method for physically separating particles based on differences in the ability of air bubbles to selectively adhere to specific mineral 2018年2月6日 Along with mechanized mining equipment, froth flotation dramatically improved the efficiency of gold mines Thanks to this process, miners and refiners are able to extract quality minerals from ore at lower grades than Recovering Gold through the Froth Flotation 2019年12月2日 Froth flotation method is one of the most widely used methods for treating pulsegold ore in gold concentrator In most cases, froth flotation method is used in the treatment of gold bearing ores with high reproducibility The Common Gold Mining Process – Froth 2025年3月4日 Froth flotation’s the answer A process that transforms lowgrade ore (like 1% copper) into high value concentrate ready for smelting Here is how it works Inside a flotation What is Froth Flotation and why is it important for mineral 2019年11月11日 Here are several combined process used for gold extraction according to different ore properties: This method is most commonly used for goldcontaining quartz dike 4 Types of Gold Ore Froth Flotation Combined Process Mining 2019年9月12日 Flotation agents are agents used in the mineral flotation process that can adjust the surface properties of minerals and increase or decrease mineral floatability,which makes ore pulp properties and foam stability more How Collector Usage Affect Froth Flotation

.jpg)

Copper Ore Processing Plant Fote Machinery

2025年4月1日 copper mine: froth flotation method Ore processing flow: 1 Crushing: Crush the copper ores to the proper size with a jaw crusher Place an impact crusher for further crushing, if necessary Then, grade ore particles 2022年3月1日 According to the processing order of the useful mineral, the copper ore processing/mining can be divided into precedence flotation, equivalent flotation, mixed flotation, and partial flotation The process choice of copper COPPER FLOTATION PLANT Pineer Mining 2015年1月30日 Copper is extracted from the ground through a multistep process involving open pit mining, crushing, froth flotation to concentrate the copper, smelting to further purify it, and electrolytic refining to produce 9998% pure copper 2 Froth flotation uses oil to make the copper minerals waterrepellent so they float, separating them from waste Floatation PPT SlideShare2009年8月27日 1 Froth Flotation – Fundamental Principles Froth flotation is a highly versatile method for physically separating particles based on the ore is not weighed and only assays will be available However, it is possible to express the ratio of concentration in terms of ore assays Starting with the mass balance equations, and the1 Froth Flotation – Fundamental Principles2025年4月2日 Flotation is a material separation method with air bubbles as the medium, also known as froth flotationIt is a beneficiation method with wide application and good effect in the separation of finegrained materials It is suitable for the separation of metal minerals and nonmetal minerals, and can also be used for the recovery, separation and purification of many raw Ore Flotation Process Solution JXSC Machinery2024年3月1日 The results from the twostage flotation conducted in the mechanical cell exhibited satisfactory performance, notably without the occurrence of sticky brown froth, which was observed during the flotation of both the asreceived feed and the deslimed product from the REFLUX TM Classifier This observation suggests a significant removal of slimes The role of enhanced desliming and gravity separation as a

Froth+flotation PPT SlideShare

2016年12月30日 Froth+flotation Download as a PDF or view online for free types of different kind of classifier on basis their settling velocities in water or air and amphibole rich rock The mine has ore reserves of 3411 million tons at 113% copper grade in the Khetri block and 2539 million tons at 169% copper grade in the Banwas block In ore/mineral beneficiation, froth flotation is a method by which commercially important minerals are separated from impurities and other minerals by collecting them on the surface of a froth layer For example, as we have discussed above, froth flotation is a technique that is used widely in the mining industry Using this technique Froth Flotation Process Detailed Explanation with Diagrams 2021年2月14日 Source: This article is a reproduction of an excerpt of “In the Public Domain” documents held in 911Metallurgy Corp’s private library Flotation of a Fluorspar Ore from Illinois This report is the fourth in a Bureau of Mines series describing the sodium fluoridelignin sulfonatefatty acid process of froth flotation separation of fluorspar from complex ores Fluorspar Beneficiation Process Plant 911Metallurgist2019年11月19日 Overview of the Groveland Mine iron ore beneficiation process, utilizing direct flotation in acidic conditions (based on Houot 1983) Overview of the iron ore beneficiation process in the Qidashan (PDF) Flotation of Iron Ores: A ReviewFroth flotation is the use of the physical and chemical properties of the surface of the ore, the use of chemical separation of useful ore In the process of froth flotation, useful minerals are separated by floating them in the foams, and the way of keeping gangue minerals in the pulp is called positive flotation, while the way of floating Mineral Flotation, Flotation Separation, Forth Flotation 2016年5月7日 A frother such as pine oil is usually added for froth control Potash Flotation The conditioner and reagentized saltbrine slurry is floated in a “SubA” Flotation Machine In the circuit shown, roughing is accomplished in a “SubA” Free Flow Flotation Machine with no intermediate weirs or feed pipesPotash Flotation Process 911Metallurgist

3 Factors Affect Froth Flotation Process? Miningpedia

2019年3月1日 The froth flotation process is a mineral processing technology with a wide application range and strong adaptability It can be applied to almost all kinds of minerals such as nonferrous metals, rare metals and nonmetals And it can process more than 100 minerals, especially for gold extractionIf the gangue mineral in an iron ore is predominantly quartz, reverse flotation is usually used in the cleaning stage to improve the concentrate grade Figure 913 presents a typical flow sheet for processing an oxidized iron ore containing about 30% Fe using a combination of SLon magnetite separators and reverse flotation The ore is mainly composed of magnetite, hematite, martite, Reverse Flotation an overview ScienceDirect TopicsSignificance of exposed grain surface area in coarse particle flotation of lowgrade gold ore with the HydroFloat technologyConventional flotation machines are typically limited to a particle topsize of 150200 microns due to inherent constraints created by the pulp and froth phasesHydroFloat Flotation Eriez2019年3月1日 It is expected that applications of convolutional neural networks, and other deep neural network architectures, will become more widespread as the technology continues to mature It is likely that these state of the art techniques could provide significant improvements for flotation froth and particle/ore sorting and sizing applicationsMachine learning applications in minerals processing: A review2016年5月26日 The classifier can be used to advantage in dewatering and controlling feed to a regrind ball or rod mill, or material from tables, jigs, or flotation CrossFlow Classifier CLASSIFIERS having a helical (often improperly called “ spiral ”) flight for removing settled coarse material have long been in successful use and most mill operators Types of Classifiers in Mineral Processing 911MetallurgistMiningpedia is a valuable and professional communication platform who focuses on providing mineral processing knowledge, Froth Flotation of Fluorite Ore Froth flotation is the main beneficiation process for fluorite beneficiation In this article, we will learn about the different types of fluorite flotation processes 5 Comparisons Miningpedia Mineral Extraction, Mineral Processing,

.jpg)

This crusher machine will be used in flotation

The flotation process consists of jaw crusher, ball mill, classifier machine, magnetic separator, flotation machine, concentrator, dryer, and other major equipment Forming a complete beneficiation production plant with ore feeder, Flotation froth is a process used in the mining industry to physically separate particles based on their ability to adhere to air bubbles It involves creating a froth containing hydrophobic particles attached to air bubbles, which can then be removed from the liquid phase (or similar) classifier into a fines stream, which is fed to the Flotation Froth an overview ScienceDirect Topics2021年4月16日 Table flotation realizes the flotation separation of easy flotation sulfide and other minerals under the condition of coarse particles, and minerals of different specific gravity can also be separated on the bed surface The applicable particle size range of the table flotation method is 3+02mm Features of Table Flotation:3 Separation Methods for Wolframite Concentrating Mining 2019年9月24日 Froth flotation is a process for selectively separating hydrophobic materials from hydrophilic,which is suitable for leadzinc oreBut the flotation of oxidized leadzinc ore is a difficult one In the treatment of leadzinc oxide ore, it is complicated to choose flotation reagent and Froth Flotation Analysis of Oxidized Leadzinc Ore2017年8月14日 Froth flotation is a pivotal process in mineral processing and industrial applications, widely employed for the separation and recovery of valuable materials By utilizing the principles of hydrophobicity and selective attachment to air bubbles, the technique enables the efficient extraction of target minerals from ores or contaminants from Flotation PPT SlideShareMiningpedia is a valuable and professional communication platform who focuses on providing mineral processing knowledge, Froth Flotation of Fluorite Ore 5 Comparisons Teach You How to Choose Spiral Classifier or Hydrocyclone? 8535 7 2Miningpedia Mineral Extraction, Mineral Processing,

7 Factors Affecting Phosphate Froth Flotation Miningpedia

2020年5月26日 Froth flotation process as a complex physical and chemical beneficiation process, flotation stage has a great impact on the phosphate beneficiation index, and the effect of this stage will directly affect the subsequent processesIn order to ensure that phosphate ore flotation get a higher process index, the key to obtain a better technical and economic index of 2019年9月19日 Let's dive in now! See the parameters how to affect froth flotation process and simple operation tips to solve it 1 Grinding Size for Froth Flotation Process Froth flotation circuit is consisted of grinding, mixing dosing, flotation separation and flotation foam products and tailings after dehydration process The grinding size of ore is one What Will Affect Froth Flotation Process And What's the 2019年9月12日 Flotation agents are agents used in the mineral flotation process that can adjust the surface properties of minerals and increase or decrease mineral floatability,which makes ore pulp properties and foam stability more conducive to mineral separation The collector,a type of organic substance that can selectively act on the surface of minerals to make the mineral How Collector Usage Affect Froth Flotation Process Mining 2019年12月2日 Where to Use Froth Flotation? Froth flotation method is one of the most widely used methods for treating pulsegold ore in gold concentrator In most cases, froth flotation method is used in the treatment of gold bearing ores with high reproducibility of sulfide minerals with good separation effectThe Common Gold Mining Process – Froth Flotation Method2019年9月12日 Flotation agents are agents used in the mineral flotation process that can adjust the surface properties of minerals and increase or decrease mineral floatability,which makes ore pulp properties and foam stability more How Collector Usage Affect Froth Flotation 2025年4月1日 copper mine: froth flotation method Ore processing flow: 1 Crushing: Crush the copper ores to the proper size with a jaw crusher Place an impact crusher for further crushing, if necessary Then, grade ore particles Copper Ore Processing Plant Fote Machinery

.png)

COPPER FLOTATION PLANT Pineer Mining

2022年3月1日 According to the processing order of the useful mineral, the copper ore processing/mining can be divided into precedence flotation, equivalent flotation, mixed flotation, and partial flotation The process choice of copper 2015年1月30日 Copper is extracted from the ground through a multistep process involving open pit mining, crushing, froth flotation to concentrate the copper, smelting to further purify it, and electrolytic refining to produce 9998% pure copper 2 Froth flotation uses oil to make the copper minerals waterrepellent so they float, separating them from waste Floatation PPT SlideShare2009年8月27日 1 Froth Flotation – Fundamental Principles Froth flotation is a highly versatile method for physically separating particles based on the ore is not weighed and only assays will be available However, it is possible to express the ratio of concentration in terms of ore assays Starting with the mass balance equations, and the1 Froth Flotation – Fundamental Principles2025年4月2日 Flotation is a material separation method with air bubbles as the medium, also known as froth flotationIt is a beneficiation method with wide application and good effect in the separation of finegrained materials It is suitable for the separation of metal minerals and nonmetal minerals, and can also be used for the recovery, separation and purification of many raw Ore Flotation Process Solution JXSC Machinery2024年3月1日 The results from the twostage flotation conducted in the mechanical cell exhibited satisfactory performance, notably without the occurrence of sticky brown froth, which was observed during the flotation of both the asreceived feed and the deslimed product from the REFLUX TM Classifier This observation suggests a significant removal of slimes The role of enhanced desliming and gravity separation as a 2016年12月30日 Froth+flotation Download as a PDF or view online for free types of different kind of classifier on basis their settling velocities in water or air and amphibole rich rock The mine has ore reserves of 3411 million tons at 113% copper grade in the Khetri block and 2539 million tons at 169% copper grade in the Banwas block Froth+flotation PPT SlideShare

.jpg)

Froth Flotation Process Detailed Explanation with Diagrams

In ore/mineral beneficiation, froth flotation is a method by which commercially important minerals are separated from impurities and other minerals by collecting them on the surface of a froth layer For example, as we have discussed above, froth flotation is a technique that is used widely in the mining industry Using this technique 2021年2月14日 Source: This article is a reproduction of an excerpt of “In the Public Domain” documents held in 911Metallurgy Corp’s private library Flotation of a Fluorspar Ore from Illinois This report is the fourth in a Bureau of Mines series describing the sodium fluoridelignin sulfonatefatty acid process of froth flotation separation of fluorspar from complex ores Fluorspar Beneficiation Process Plant 911Metallurgist

如何用参振重量和振幅计算高细立磨轴承受力如何用参振重量和振幅计算高细立磨轴承受力如何用参振重量和振幅计算高细立磨轴承受力

--矿山成本核算表格模板

--煤炭技术投稿系统

--煤粉碎机械多少钱一台

--矿石那的好

--方解石磨粉机师傅

--工业制粗硅的设备

--贵州方解石超细磨粉机

--菱锰深加工

--露天方解石矿采矿工艺流程

--方解石厂咋么开石头

--浙江建德方解石欧版磨粉机生产案例

--水泥配制站申请条件水泥配制站申请条件水泥配制站申请条件

--粉碎厂的销售报表

--铝矾土粉磨

--煤焦工业磨粉机厂家艺流程

--方解石磨粉机

--ggh脱硫设备

--玻璃粉碎机工作视频

--空心砖种类

--色选机在石英砂石灰石生产中应用

--伊利石生产线价格伊利石生产线价格伊利石生产线价格

--小功率矿石磨粉机

--辊磨机与悬工业辊磨机工作原理上有何区别

--矿粉粉雷蒙磨

--陶瓷原料粉机械化

--亿丰粉碎机械

--CYM

--磨煤机和碎煤机

--SCBF900电石泥磨粉机杀磨机

--