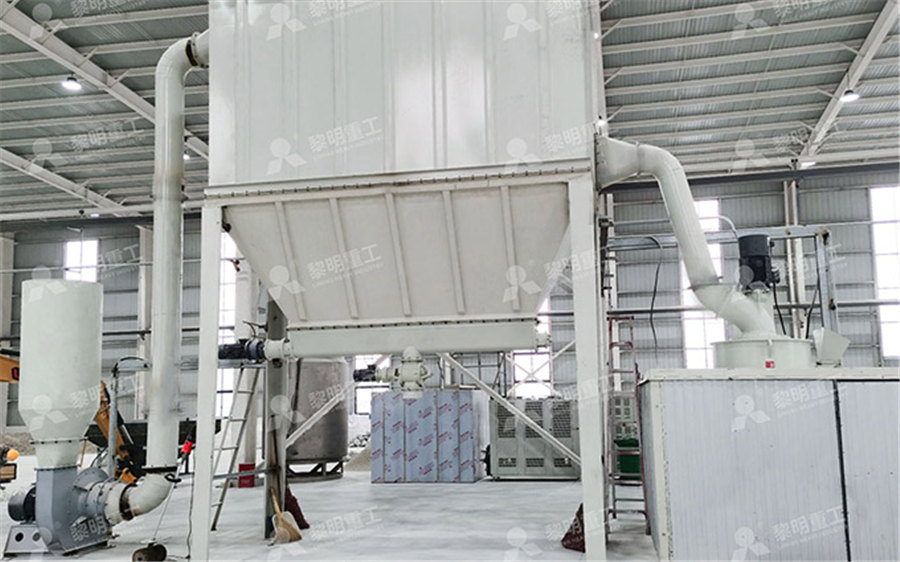

细粉加工设备(20-400目)

我公司自主研发的MTW欧版磨、LM立式磨等细粉加工设备,拥有多项国家专利,能够将石灰石、方解石、碳酸钙、重晶石、石膏、膨润土等物料研磨至20-400目,是您在电厂脱硫、煤粉制备、重钙加工等工业制粉领域的得力助手。

超细粉加工设备(400-3250目)

LUM超细立磨、MW环辊微粉磨吸收现代工业磨粉技术,专注于400-3250目范围内超细粉磨加工,细度可调可控,突破超细粉加工产能瓶颈,是超细粉加工领域粉磨装备的良好选择。

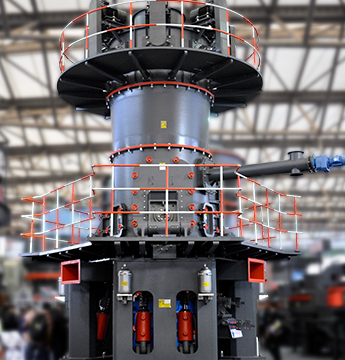

粗粉加工设备(0-3MM)

兼具磨粉机和破碎机性能优势,产量高、破碎比大、成品率高,在粗粉加工方面成绩斐然。

Secondary And Primary Rolls For Quarry Mining Mills

.jpg)

Construction, Working and Maintenance of Practical

2018年12月26日 low speed sizers, impactors and hammer mills are used as primary crushers In the secondary and subsequent stages, the material is further reduced and refined for proper 2023年2月28日 Primary crushing is the first stage in the comminution process and involves breaking down large rocks into smaller pieces that can be handled by the downstream machinery Secondary crushing, on the other hand, is the The Complete Guide to Primary Crushing, 2023年2月28日 Both primary and secondary crushers are used in a variety of realworld applications In mining, primary crushers are used to break down large rocks and stones into smaller particles for further processing Secondary Primary Crusher vs Secondary Crusher: 2025年3月18日 Gyratory crushers, sand making machine, jaw crushers, and impact crushers are used for primary and secondary crushing After crushing, the size of the material is further What is the Process of Quarrying? Zenith CrusherDouble crushers are successful for both primary and secondary crushing when minimizing fines These machines reduce via impact, shear, and compression The rolls provide toothed patterns suited to the feed material Single Roll Roll Crushers Williams Patent Crusher2020年7月10日 The degree to which material is reduced through stages of primary, secondary, and tertiary crushing can depend on the type of material, like aggregate, concrete, and asphalt, and can also depend on the variety of What Is Primary, Secondary, and Tertiary Crushing?

Secondary Crushing Equipment 911Metallurgist

2016年2月29日 The simple twocrusher, screenless arrangement works out fairly well for the large sizes of primary jaw crushers if the quarryrun rock is reasonably clean, or if any fine material which may be present in the feed is Related to information of process of crushing with primary secondary tertiary crushing primary secondary tertiary crushers Different crushing operations Cone Crushers – Industrial Different Types Of Crushers Machine Of Primary,secondary Roll Crushers are designed to handle the primary, secondary and tertiary stage crushing of friable materials such as coal, salt, clay, bauxite, limestone and other minerals of similar Mining Primary And Secondary Crushers aipmco2013年4月10日 how to differentiate primary ball mill and secondary ball mill As a professional crushing and grinding equipments manufacturer, kefid can supply you all kinds of open circuit primary ball mill for wet grinding miniprimary ball mills Mining Quarry Plant2024年4月19日 The primary crushing stage is the first stage of the crushing process This is where the bulk of the rocks or ore are crushed to make them manageable in the next crushing stages The primary aim of the primary Types of Crushers Explained: Everything You 2018年12月26日 Generally gyratory crushers, jaw crushers, high speed double roll crushers, low speed sizers, impactors and hammer mills are used as primary crushers In the secondary and subsequent stages, the material is further reduced and refined for proper size and shape, mostly based on specifications Most secondary crushers are cone crushers andConstruction, Working and Maintenance of Practical

Primary Crusher an overview ScienceDirect Topics

21 The primary crusher The primary crusher is located in the quarry and consists of a McLanahan 48″x72′ Shale King Crusher rated at 1,000 TPH (Tons Per Hour) The driving flywheel has a diameter of 25 meters and is motor driven through six vbelts The capacity of the primary crusher had to be increased to 1,250 TPH to produce enough material to serve the wet and 2013年4月21日 Hot Products Used for quarry primary and secondary crushing vsi crusher hpc cone crusher belt conveyor scm ultrafine mill mobile crusher pew jaw crusherquarry primary and secondary crushing Grinding Mill ChinaPrimary Crushing The purpose of the primary crusher is to reduce the ROM ore to a size amenable for feeding the secondary crusher or the SAG mill grinding circuit The ratio of reduction through a primary crusher can be up to about 8:1 Feed: ROM up to 15 m; Product: 300mm (for transport) to 200mm (for SAG mill) Feed Rate: 160 to 13,000 tphAMIT 135: Lesson 5 Crushing – Mining Mill Operator Training2017年3月4日 The double jaw crusher is designed for crushing hard materials, also quarried materials, sand and gravel, and recycling [4, 5] crusher [4] The tie rod and compression spring ensure that the (PDF) SIZE REDUCTION BY CRUSHING METHODS2013年3月20日 Ball mill is used as secondary grinding equipment in rock quarry plants in mining industry VERTIMILL grinding mill,Primary and Secondary Fine how to differentiate primary ball mill and secondary ball secondary ball mills Mining Quarry Plant2016年1月17日 In mineral processing, the reduction of minerals by crushing and grinding may be regarded as having one or other of two main objectives: the attainment of a size appropriate for the direct industrial application of the mineral, eg barytes, sand, aggregate; or the release of metallic or ore inclusions from an unwanted matrix with a view to maximum separationCrushing Mineral Processing 911Metallurgist

.jpg)

Crushing Plant Design and Layout Considerations 911

2024年9月24日 Mine haultruck capacity is an important factor at primary crusher installations, because it is costeffective to integrate truck cycle time at the crusher station with mine/shovel operations If a primary crusher dump pocket is undersized and unable to handle the mine’s trucks, then operators must slowly meter the ore into the receiving hopperThe Original Mining Tools Explosives (gunpowder etc) were introduced to commercial mining during the industrial revolution; using explosives to mine is referred to as ‘blasting’ Blasting came into widespread use for bulk mining in Gyratory Crusher (Gyratory Crushers Explained)2016年2月29日 The term “secondary crushing” has become well established and familiar through long usage; it applies to the crushing stage, either single or multiple, which follows immediately after the primary crusher, taking all or a Secondary Crushing Equipment 911MetallurgistOne of the most versatile crushers available, hammer mills and impactors can be primary, secondary, and tertiary crushers Hammer mill crushers use continuous hammer blows to shatter and disintegrate material Mining Industry: In the Types of Crushers: What you need to knowIf you need iron ore crusher,gold ore crusher,copper ore crusher or other mining machinery,you can contact rock breaker for iron ore gyratory crusher and roll rolls crusher copper ore Mining Quarry PlantApplication area : Primary/ Secondary Ball Mill / Regrind Mill , FAG / SAG Mill Description:"Depending on the duty condition, selection of metal OrientalBall Mill,Ball Mill For Sales,Price List,Manufacturersecondary ball mill Mining Quarry Plant

.jpg)

Ball Mill Secondary Jaw Crusher Crusher Mills, Cone

There are primary crusher and secondary crusher for quarry mining CEMENT BALL MILL VERTICAL COAL MILL SUPER THIN MILL 02 New crushers Jaw crusher for saleJaw crushers are truly the bedrock of any material processing work in both the mining and construction worlds They play an essential part in smashing up big, tough chunks of material into smaller bits, preparing them for the next steps where these valuable bits of earth are processed and valuable minerals are pulled outUnderstanding Types of Jaw Crusher: A Comprehensive 2012年11月14日 10% in minetomill activities • Reduces greenhouse emissions by reducing use of explosives Applications in Our Nation’s Industry The aggregates industry, representing the largest segment of the US mining industry, will benefit the most from minetomill technology, focusing on particle size control rather than particle size reductionITP Mining: MinetoMill Optimization Energygov2021年7月14日 Primary Crusher Product Mining Metallurgy primary (unscreened) and secondary mine, but the usual practice in mining operations is to scalp off most of the undersize ahead of the primary crusher, » Free online chat! Primary Crusher Mining Metallurgy – Mining and Metallurgical Mining MetallurgyPrimary Crusher These dimensions primary and secondary crusher mining – Grinding Mill China2015年4月24日 It then describes the stages of primary, secondary, and sometimes tertiary crushing needed to reduce the ore size The main types of primary crushers are jaw and gyratory crushers, while cone crushers are often Roll crushers PPT SlideShare2021年3月25日 The primary crushing stage at the top of the machine and the secondary stage at the bottom of the machine both consist of a doubleroll arrangement Due to the feed opening and design of the top stage, these What Type of Crusher Is Best for Primary

Crushing Plant Flowsheet DesignLayout 911Metallurgist

2016年3月11日 To reduce runofmine to mill feed requires reduction in a series of stages The physical size and power requirements of a crusher capable of reducing hard rock vary depending on the application Extended experience in most crushing plants show that a minus 19MM (¾”) rod mill feed can be and is being produced in three stages of crushing2015年10月28日 The output gradation of the primary HSI crusher is generally coarser than the primary breaker due to the lack of expansion above the rotor, which also affects the capacity Primary HSI crushers are considerably wider than primary breakers at comparable capacity ratings Secondary horizontalshaft impact (HSI) crushersSelecting the Right Crushing Equipment AggNet impact style and roll style crusher; ball mill, stone crusher; sand mobile crusher for crushing stone, rock, quarry materials in mining industry mabati rolling mills prices galsheet stone crusher quarryRoll Mill Quarry Big Stone Crusher Crusher Mills, Cone 2015年4月16日 History tells us, it was in 1830, the first US patent was issued on a rock crushing machineIt covered a device which, in a crude way, incorporated the drop hammer principle later used in the famous stamp mill, whose history is so intimately linked with that of the golden age of miningIn 1840, another patent was issued, which comprised a wooden box containing a Rock Crusher History 911Metallurgist2024年7月15日 Depending on the physical characteristics of raw material, one of the roll crusher typesdouble roll crusher can provide a reduction ratio with 3:1 in some applications while another typetriple roll crusher 3:1 That makes roll crusher performs also well on hard and abrasive materialWhat Are the Differences Between The 7 Types of Crushers?2023年2月28日 Secondary crushing is the second stage of crushing that takes place after the primary crushing The secondary crusher is the equipment that reduces the size of the materials further, after they have been reduced by the primary crusher The secondary crusher has a size reduction ratio ranging from 3:1 to 5:1Primary and Secondary Crushing: Understanding the Basics

.jpg)

Metso Partner for positive change Metso

2024年1月10日 The Metso Crushing and Screening Handbook covers rock processing, aggregates production, equipment, and various processing methods2013年4月10日 how to differentiate primary ball mill and secondary ball mill As a professional crushing and grinding equipments manufacturer, kefid can supply you all kinds of open circuit primary ball mill for wet grinding miniprimary ball mills Mining Quarry Plant2024年4月19日 The primary crushing stage is the first stage of the crushing process This is where the bulk of the rocks or ore are crushed to make them manageable in the next crushing stages The primary aim of the primary Types of Crushers Explained: Everything You 2018年12月26日 Generally gyratory crushers, jaw crushers, high speed double roll crushers, low speed sizers, impactors and hammer mills are used as primary crushers In the secondary and subsequent stages, the material is further reduced and refined for proper size and shape, mostly based on specifications Most secondary crushers are cone crushers andConstruction, Working and Maintenance of Practical 21 The primary crusher The primary crusher is located in the quarry and consists of a McLanahan 48″x72′ Shale King Crusher rated at 1,000 TPH (Tons Per Hour) The driving flywheel has a diameter of 25 meters and is motor driven through six vbelts The capacity of the primary crusher had to be increased to 1,250 TPH to produce enough material to serve the wet and Primary Crusher an overview ScienceDirect Topics2013年4月21日 Hot Products Used for quarry primary and secondary crushing vsi crusher hpc cone crusher belt conveyor scm ultrafine mill mobile crusher pew jaw crusherquarry primary and secondary crushing Grinding Mill China

.jpg)

AMIT 135: Lesson 5 Crushing – Mining Mill Operator Training

Primary Crushing The purpose of the primary crusher is to reduce the ROM ore to a size amenable for feeding the secondary crusher or the SAG mill grinding circuit The ratio of reduction through a primary crusher can be up to about 8:1 Feed: ROM up to 15 m; Product: 300mm (for transport) to 200mm (for SAG mill) Feed Rate: 160 to 13,000 tph2017年3月4日 The double jaw crusher is designed for crushing hard materials, also quarried materials, sand and gravel, and recycling [4, 5] crusher [4] The tie rod and compression spring ensure that the (PDF) SIZE REDUCTION BY CRUSHING METHODS2013年3月20日 Ball mill is used as secondary grinding equipment in rock quarry plants in mining industry VERTIMILL grinding mill,Primary and Secondary Fine how to differentiate primary ball mill and secondary ball secondary ball mills Mining Quarry Plant2016年1月17日 In mineral processing, the reduction of minerals by crushing and grinding may be regarded as having one or other of two main objectives: the attainment of a size appropriate for the direct industrial application of the mineral, eg barytes, sand, aggregate; or the release of metallic or ore inclusions from an unwanted matrix with a view to maximum separationCrushing Mineral Processing 911Metallurgist2024年9月24日 Mine haultruck capacity is an important factor at primary crusher installations, because it is costeffective to integrate truck cycle time at the crusher station with mine/shovel operations If a primary crusher dump pocket is undersized and unable to handle the mine’s trucks, then operators must slowly meter the ore into the receiving hopperCrushing Plant Design and Layout Considerations 911

汉源硅石石灰石碳酸钙磨粉机械厂家

--矿石磨粉机工作原理

--破混凝土设备

--400200型环保型锺式矿石磨粉机

--100的粉磨机油压多少

--研磨机价格

--粉煤灰机报价

--煤矸石的可磨系数

--1000TPH无烟煤微粉磨

--水泥粉煤灰稳定土配合比例矿石磨粉机6090价格

--方解石打粉生产线地基图

--液压重石灰石雷蒙磨

--超细摆式磨粉机5MR×4419

--宏达矿业为什么涨这么多

--双进双出磨煤机钢球

--热电水塔混凝土用石膏粉碳酸钙还是雷蒙磨石

--煤炭采矿许可证办理

--小型雷蒙磨厂价格

--蕨根粉碎机

--氧化镁加工

--方解石可以做高钙粉吗

--拌合机安全验收制度

--裂解炭黑 高钙粉

--方解石菱镁矿磨粉机

--矿山研磨机

--上海重晶石矿加工厂

--矿渣球磨机设备

--福建莆田颜料加工粉磨设备

--混凝土可以加粉碎裂解炭黑代替重钙粉吗

--辊式l矿石磨粉机

--